Workstation light crane systems are a type of user-friendly, ergonomic light gantry crane that enable operators to perform otherwise laborious material handling tasks with ease, while reducing the risk of injury.

Often used in manufacturing plants, workstation light overhead cranes typically have a lifting capacity of up to 2,000kg, lift from a hoist or intelligent lifting device situated under the ‘bridge’, and feature optimised steel profiles that are renowned for having the best weight to load capacity ratio in the industry. This ensures maximised suspension distances and leads to significant realised savings, thanks to reduced material costs (such as the steel supporting construction), fewer suspension components, and faster installation times.

Workstation light cranes are known for their smooth operation, freedom of movement, ease of use, and effective performance, providing manufacturing operations with a dedicated assisted lifting capability to improve the efficiency and safety of material handling tasks, increasing production outputs.

The Workstation System

What are workstation light crane systems used for?

Workstation light gantry cranes are used in a wide variety of applications, but are predominantly found in production lines, factories, workshops, and light industrial manufacturing operations where finished goods, componentry, and raw materials need to be repeatedly lifted and transported from one location to another within the same facility.

Workstation light crane systems have a number of benefits over traditional larger gantry overhead crane setups:

- Best-in-class weight to load capacity ratio, improving cost-efficiency.

- Highly adaptable - can be configured to suit the task at hand, and disassembled and moved location, should operational requirements change.

- Installed either freestanding or suspended/fixed to the building structure, with a comparatively fast installation/disassembly (against other crane types), reducing downtime.

- Freedom of movement - perfect for repetitive tasks and precision operation.

Why use a workstation light overhead gantry crane?

Workstation light crane systems feature freedom of movement that is unseen with larger, bulkier cranes. Perfect for precise, repetitive tasks, workstation cranes are great at supplementing forklift fleets or jib crane systems, workstation cranes are known for being operator user-friendly and improving productivity.

Highly durable due to their closed profile construction which prevents the system from being exposed to dust, workstation cranes feature steel profiles which are surface treated with impact resistant powder coating to provide further protection and longevity.

A selling point of workstation cranes is that the lifting device (typically a hoist) and trolley can be replaced if required, improving the adaptability and longevity of the entire system.

All connections in the system are bolt connections which make the system easy to install and easy to adapt to changing layout requirements. The patented hoist trolley runs inside the track profile and features special nylon wheels with sealed bearings making the trolley movement almost effortless, with a rolling resistance of only approximately 1% of the moved load.

With a large range of accessories available, almost any requirement can be met, guaranteeing a high level of operational capability and risk mitigation, while keeping investment costs in check.

Is a workstation light overhead gantry crane a bridge crane?

As is often the case in our industry, terminology tends to get mixed with varying results, and workstation light overhead cranes are no exception.

A workstation light crane may go by many names: Light gantry crane, overhead crane, work station crane, track crane, and bridge crane to name a few - all of these labels are used interchangeably throughout the industry to describe a workstation crane system.

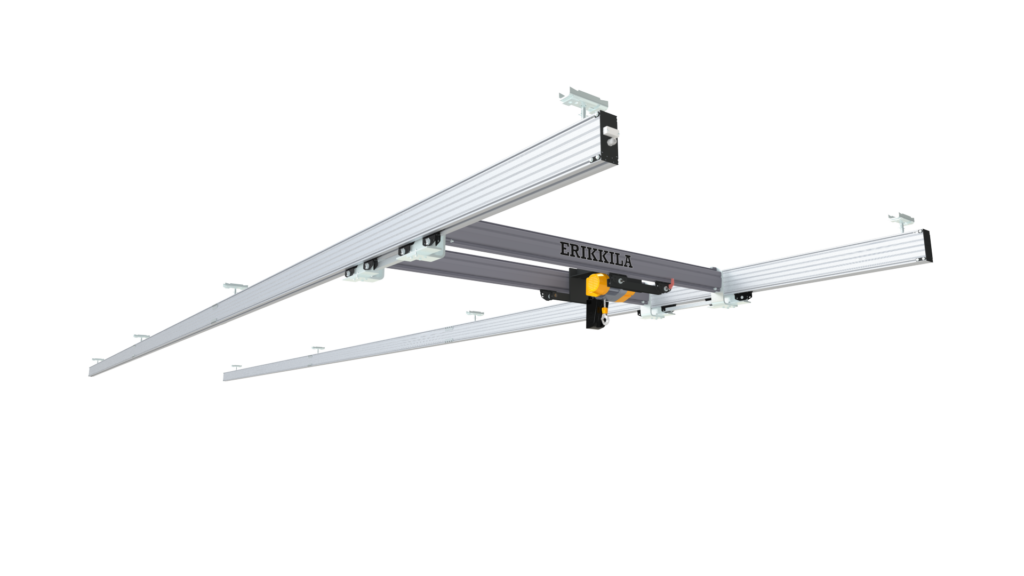

The ‘bridge’ in the bridge crane is the overhead cross-beam that sits between two parallel tracks of the workstation crane. The hoist trolley runs across the 'bridge' providing the left-to-right positioning of the hoist. The bridge is occasionally referred to as a ‘girder’, but it is important to note that a workstation crane is not a heavy girder or heavy bridge crane.

- To learn more about girder cranes and the differences therein, refer to our single girder cranes page to begin with.

Is a workstation light crane system a type of jib crane?

No. Another important distinction is that the workstation light crane systems we design and supply are overhead (or bridge) cranes by definition, and do not feature the cantilevered jib arm design that people commonly associate with cranes in general.

However, we do supply jib crane systems that are well suited to assisting in a set workspace environment. Two variants that fit this criteria are column mounted jib cranes and wall mounted jib cranes - both of which feature the classic jib arm design, meaning they do not feature a bridge for the hoist or lifting device to run along, but are a great choice for repetitive tasks in a fixed workspace where the work radius is defined.

It is not uncommon to see both workstation cranes (and larger gantry cranes) and jib crane systems sharing a single workspace such as a factory floor or logistics centre.

- If interested in a crane with a jib arm design (including wall mounted, column mounted, and industrial manipulator variants), our jib cranes section has you covered.

Can workstation light crane systems be customised for tailored use?

Highly adaptable, workstation light crane systems can be precisely configured for specific loads and layouts, and can feature either single or double tracked bridges to meet the required load capacity.

We are able to customise workstation light cranes to meet your required application, and can provide custom paint jobs and surface treatments (including hot dipped galvanising) on request.

Let us do the heavy lifting for you

Workstation light overhead gantry cranes can play an important role in many material handling operations, but, as with all heavy machinery, care must be taken to ensure that the proposed usage meets the appropriate application and does not exceed technical limitations.

The team at Stratalign are the workstation light crane system experts. Our knowledgeable team of problem solvers can help you to choose the correct workstation light overhead crane setup for your needs, improving the efficiency and safety of your material handling operation by ensuring you have the "right tool for the job".

Applications

Raised Dual Bridge Low Headroom Light Crane

Freestanding Workstation Light Cranes

Suspended Aluminum Profile Workstation Light Crane

Our Process

Palmerston North City Council - Case Study

The Requirement

The Challenge

Solution to a long-standing challenge

As a solution to a long standing challenge, Cabtec Ltd purchased a Fezer vacuum lifter from Stratalign Limited, for processing product through a processing line. Prior to the purchase, the process had required manual handling, which in today's environment, is not a sustainable option.

More than one option for this solution was investigated by Cabtec with the decision being a vacuum lifter as the winning choice. Cabtec's spokesman recalls, Cabtec selected Stratalign as the winning supplier, based on their ability to provide the technical and professional advice, along with what Cabec considered a top quality product for a competitive price

.

The ease of operation

is facilitated by the very smooth running bearings and movement points, integral to this structurally sound piece of kit. He continues, From the day the order was placed, the Stratalign team kept us updated with progress, to the day the machine was installed.

The installation process was organized in such a way, by Stratalign, that it caused absolute minimal disruption to a very busy working environment during normal working hours.