Vacuum tube lifters are an innovative type of vacuum lifter, suitable for lifting sacks, cardboard boxes, drums, plates, and other items up to 200kg.

Utilising vacuum technology, tube lifters excel at driving productivity where repetitive tasks are involved. With their single-handed operation, tube lifters are a practical, simple, safe, cost-effective handling device that offer a smooth, fast, consistent lifting function for smaller items, removing the burden of manually handling those same goods - or over-engineering a lifting solution which is not required for such a load.

Tube lifters provide enormous extra benefit through increased ergonomics, and vastly improve the output of material handling and industrial operations.

When should you use a tube lifter?

Often found in warehouse operations, assembly line production, or high-volume product handling needs, tube lifters handle raw materials, rounded cans, bagged goods, parcels, cardboard boxes, luggage, windows or doors, oriented strand board (OSB) and other wood products, and more.

One of the primary reasons to go with a tube lifter is the ability to lift or lower the device using just one hand, meaning that the operator can determine the handling process speed. This has a few benefits in itself, but chief among them is safety - and a safer workplace is a more effective workplace.

Another key consideration for using a tube lifter is the relatively low maintenance requirement and overall cost-effectiveness of the device. With no additional lifting aids (such as chain hoists or wire balancers) required, you can use the same medium for engagement and lifting - vacuum - improving operational efficiency and saving on investment costs.

How do tube lifters work?

Able to grip and lift various types of loads and consist of a vacuum pump connected by an air hose to a lifting tube. The suction head and suction foot at the end of the lifting tube utilise vacuum technology to hold the load in place during transit, with the load then being transported by the vacuum tube lifter’s arm to its desired location.

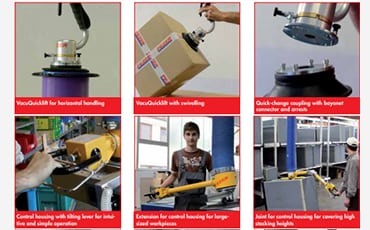

To achieve this outcome, an integrated non-return valve is installed in the upper turning head. The required vacuum is built up by powerful, low-maintenance and robust vacuum generators like oilless vacuum pumps, belt-driven blowers or multi-stage ejectors that run on compressed air. The unique modular system enables tube lifters to be tailored to individual requirements in a simple, straightforward way.

A multitude of suction feet is available to allow the transport of different goods. Extensions for the control handle, turning and swivel features and various adaptors are available to adjust the tube lifters to personal needs and requirements.

Please note: In the event of a power failure the loads are not just dropped off, but are lowered slowly to the ground, safeguarding people and property from potential harm or damage.

Let us do the heavy lifting for you

Vacuum tube lifters can play an important role in many material handling operations; but, as with all heavy machinery, care must be taken to ensure that the appropriate technical limitations of the equipment are respected and its use is as intended.

Our experienced team of engineers and technical staff can help you choose the tube lifter that meets your needs, improving the efficiency and safety of your building site or material handling operation by ensuring you have the ‘right tool for the job.’

Let us do the heavy lifting for you. Contact us today for a no-obligation consultation and quote.

Applications

Our Process

Tawa Door Company - Case Study

The Requirement

The Challenge

Solution to a long-standing challenge

As a solution to a long standing challenge, Cabtec Ltd purchased a Fezer vacuum lifter from Stratalign Limited, for processing product through a processing line. Prior to the purchase, the process had required manual handling, which in today's environment, is not a sustainable option.

More than one option for this solution was investigated by Cabtec with the decision being a vacuum lifter as the winning choice. Cabtec's spokesman recalls, Cabtec selected Stratalign as the winning supplier, based on their ability to provide the technical and professional advice, along with what Cabec considered a top quality product for a competitive price

.

The ease of operation

is facilitated by the very smooth running bearings and movement points, integral to this structurally sound piece of kit. He continues, From the day the order was placed, the Stratalign team kept us updated with progress, to the day the machine was installed.

The installation process was organized in such a way, by Stratalign, that it caused absolute minimal disruption to a very busy working environment during normal working hours.