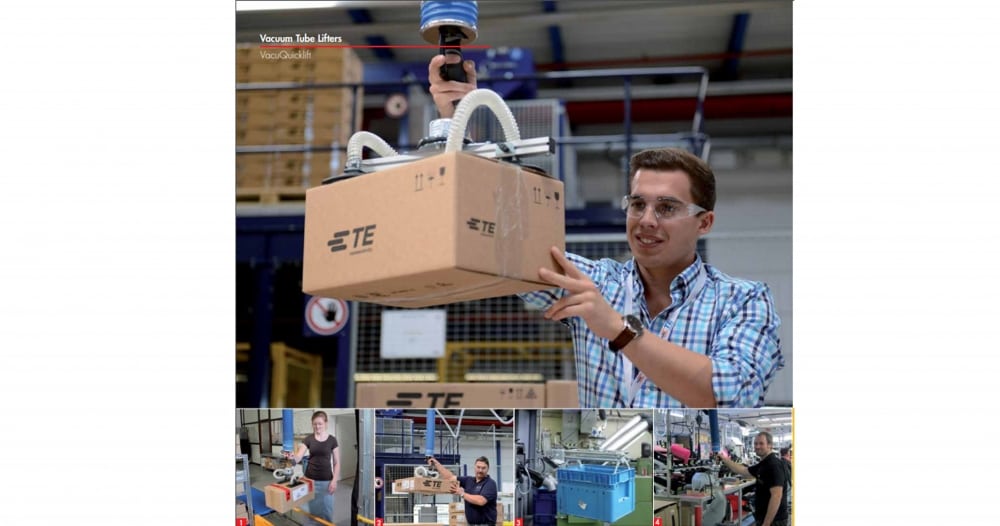

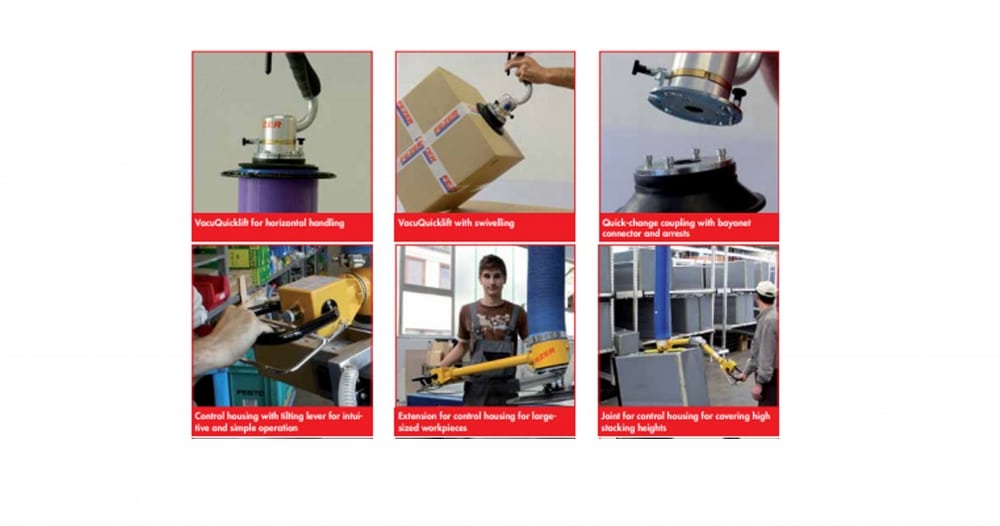

Vacuum lifters are one of the most commonly used products for dealing with different work pieces. Gentle, safe & quick lifting technology. Whether you need to lift drums, place stone slabs, move plate steel or wood panel, vacuum lifters technology allows you to carry out your handling tasks in a gentle, safe and quick manner. Vacuum lifting devices will provide reliable support in the most difficult of handling operations.

Loads can be carried effectively in the horizontal and vertical positions – ideal for glass, steel sheets and timber panels etc. Vacuum lifters can be fitted with single or multi point suction cups that can be individually switched on or off at any time. This allows the same head set up to be for a variety of applications. Battery powered units for outside applications i.e. glass window installation are available. Vacuum lifters fitted with a fork hoist attachment activated by remote control enables many products to be effectively moved both indoors and outdoors.

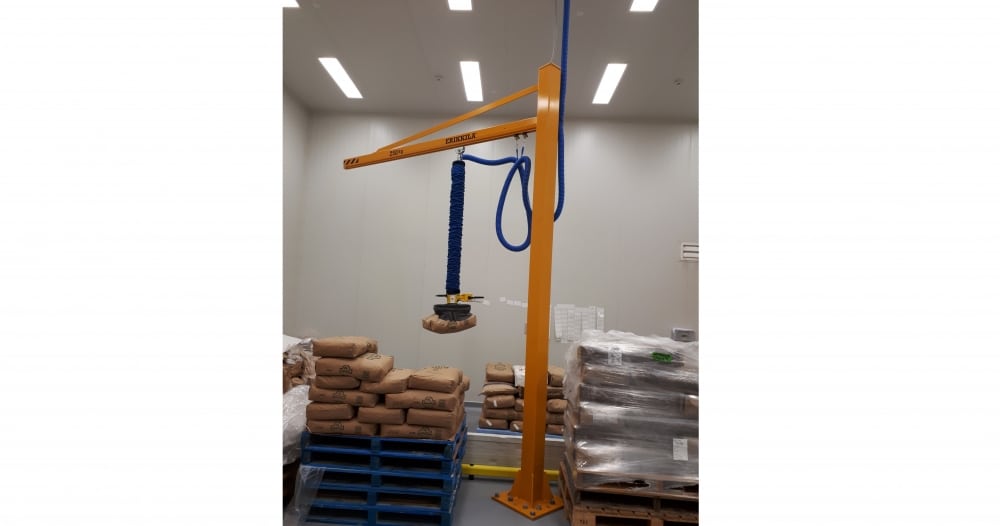

An on-site planning service is available to provide informative advice as to which unit and design best suits your application. Stratalign provides complete systems including free-standing and wall mounted jib cranes along with a diverse range of electric chain hoists to compliment your vacuum lifter.

Let us do the heavy lifting for you

Looking to learn more about our range of vacuum lifters?

Contact us today for an obligation-free consultation now to leverage our decades of experience and get the right solution for your material handling requirements.

Gallery

Our Process

Tawa Door Company - Case Study

The Requirement

The Challenge

Solution to a long-standing challenge

As a solution to a long standing challenge, Cabtec Ltd purchased a Fezer vacuum lifter from Stratalign Limited, for processing product through a processing line. Prior to the purchase, the process had required manual handling, which in today's environment, is not a sustainable option.

More than one option for this solution was investigated by Cabtec with the decision being a vacuum lifter as the winning choice. Cabtec's spokesman recalls, Cabtec selected Stratalign as the winning supplier, based on their ability to provide the technical and professional advice, along with what Cabec considered a top quality product for a competitive price

.

The ease of operation

is facilitated by the very smooth running bearings and movement points, integral to this structurally sound piece of kit. He continues, From the day the order was placed, the Stratalign team kept us updated with progress, to the day the machine was installed.

The installation process was organized in such a way, by Stratalign, that it caused absolute minimal disruption to a very busy working environment during normal working hours.