Description

A freestanding monorail crane is a versatile material handling system designed for efficient linear movement of loads in industrial settings such as manufacturing plants, warehouses, and assembly lines. Unlike overhead cranes, which operate on a bridge structure, a monorail crane consists of a single track or beam along which a hoist or trolley moves, enabling precise load transportation along a fixed path.

The freestanding design means it is supported by its own columns, eliminating the need for ceiling mounting and making it ideal for facilities with structural limitations. This setup provides flexibility in installation and can be easily relocated or expanded as workflow requirements change. Freestanding monorail cranes improve productivity, reduce manual lifting strain, and are commonly used in applications requiring repetitive lifting and movement along a defined route, such as conveyor loading, assembly operations, and workstation material transport.

Enclosed Track Profile

STEEL ENCLOSED PROFILES

The steel-enclosed profiles come in four sizes, P125, S140, S200 and S260 and are made of high-tensile steel, which allows higher stresses and bigger suspension loads. The steel-enclosed profiles allow 300 kg upward forces when equipped with an SW trolley. The steel-enclosed profiles have a world class weight–load carrying capacity ratio. All steel-enclosed profiles are rolled from one metal sheet to precise tolerances. Each enclosed profile’s cambering and opening are measured to ensure the highest quality. The S200 and S260 profiles can be equipped with an internal conductor rail (ICR).

ALUMINIUM ENCLOSED PROFILES

Aluminium enclosed profiles come in four sizes, Alu 2/105, Alu 3/140, Alu 4/180 and Alu 5/220 and are made of high-quality anodised aluminium. They have outstanding geometry and can take up to 500 kg upward forces with a standard trolley. The enclosed profiles allow smooth and light operation of the hoist and bridge. The enclosed profiles have unique ID stripes to help with identification and installation. Alu 4/180 and Alu 5/220 can be equipped with an internal conductor rail (ICR).

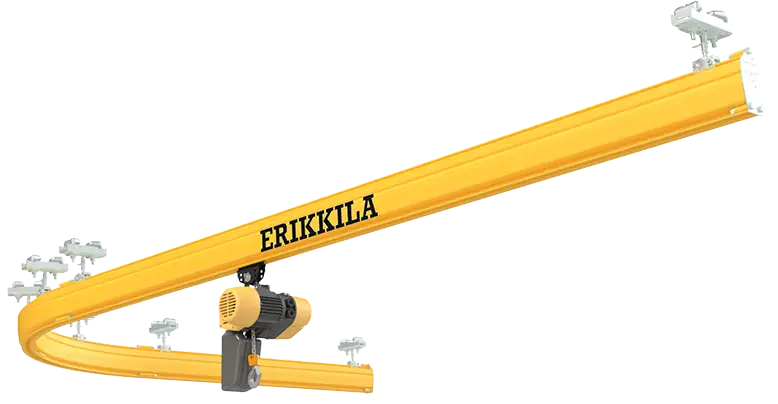

Hoist Tracks

Hoist tracks suit production lines where products must be moved long distances. With curves, turntables and track switches, the system can be tailored to meet the most challenging needs.

HOIST TRACK - STEEL

A versatile and economical solution for moving and lifting loads to 1500 kg.

HOIST TRACK - ALUMINIUM

A versatile and economical solution in aluminium for moving and lifting loads to 1000 kg.

HOIST TRACK CURVED - STEEL

Steel hoist tracks with up to 1250 kg capacity can be equipped with curves. The curves can be connected to other curves or straight profiles.

Powered Movements

POWERED MOVEMENTS FOR THE TROLLEY AND BRIDGE OF A WORKSTATION BRIDGE CRANE

Powered movements for the trolley and bridge are recommended if the crane’s rated capacity is more than 1500 kg, the lifting height is more than 6 m, or the bridge span is longer than 8 m. All powered movements of the trolley and bridge are equipped with limit switches so the units do not power into the end stops. A crane with electrical trolleys is typically controlled with a radio remote control. This means the operator can stand well clear of the load being transported. The power supply is provided by an internal conductor rail or flat cable system.

Powered Feed Systems

INTERNAL CONDUCTOR RAIL

The aluminium profiles 4/180 ICR and 5/220 ICR and steel profiles S200 ICR and S260 ICR can be equipped with an internal conductor rail to maximise the crane’s coverage. Inside the profile, the power supply is safe from external exposures, allowing full trolley and bridge movements without hanging cables.

| INTERNAL CONDUCTOR RAIL - STEEL | INTERNAL CONDUCTOR RAIL - ALUMINIUM |

|---|---|

|

|

FLAT CABLE POWER

All Workstation cranes can be fitted with a high-quality flat cable power supply. This system includes plastic cable trolleys with plastic wheels running inside the profile, supporting the flat cable. To prevent the trolleys from restricting the working area, one side of the track can be extended to accommodate the accumulation of cable trolleys.